Ordering

Ramsys POS Ordering

Operations/Order Stock

The Ramsys POS ordering screen streamlines the stock ordering process for managers by allowing quick and efficient order creation.

The system automatically generates purchase orders in Ramsys Central and once approved emails them directly to suppliers, reducing manual workload and ensuring timely restocking. With intuitive controls and real-time stock data, managers can make informed purchasing decisions, keeping inventory levels optimised and operations running smoothly.

Note: this function must be enabled in your system setup.

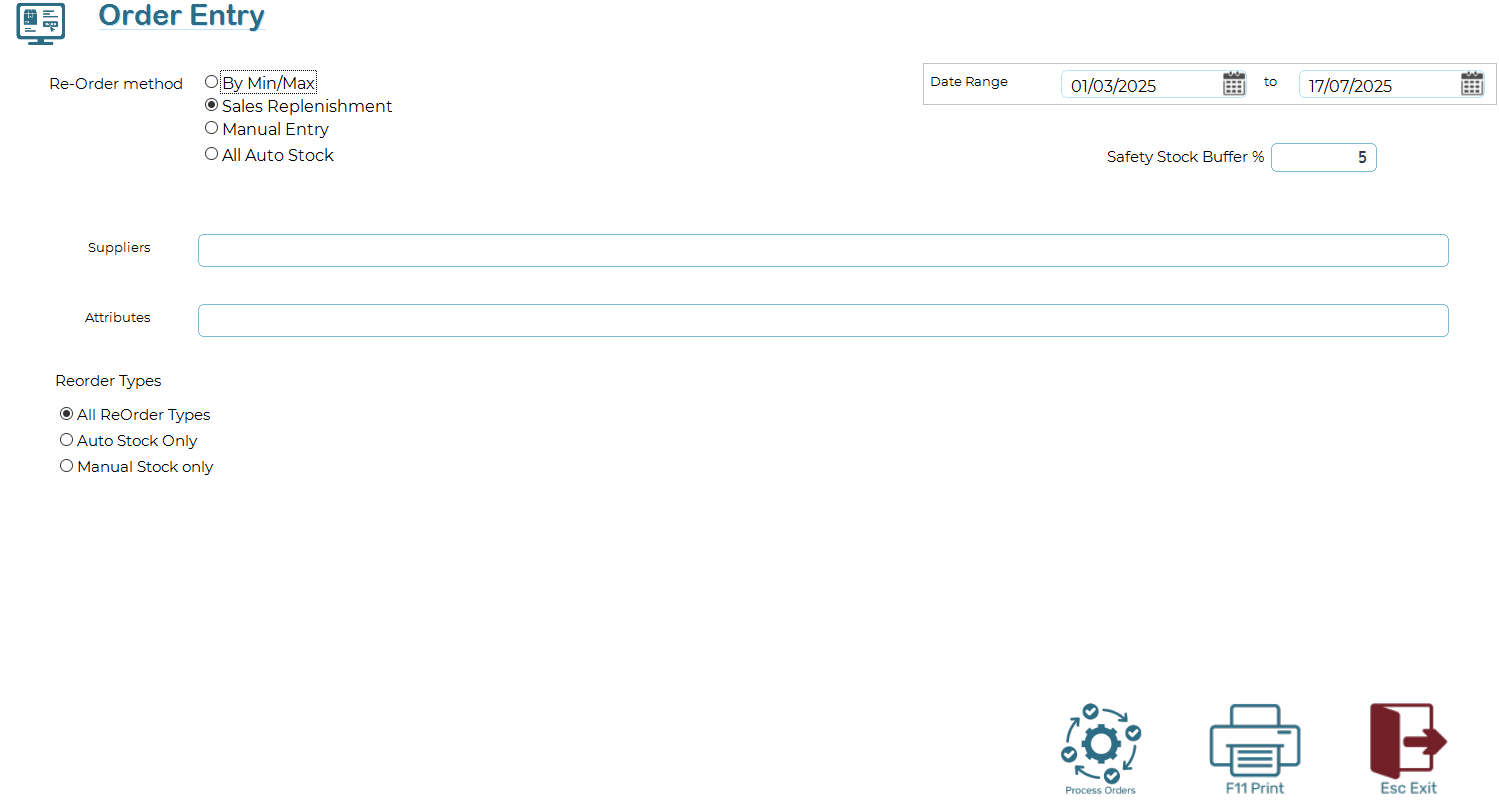

The initial screen allows you to select the type of order processing you wish to use.

By Min/Max

Min-Max ordering ensures optimal stock levels by automatically generating purchase orders when inventory falls below the set minimum quantity. The system replenishes stock up to the defined maximum level, preventing shortages and overstocking. This method helps maintain efficient inventory management with minimal manual intervention.

Sales Replenishment

Sales replenishment ordering generates purchase orders based on recent sales data, ensuring stock levels align with demand. The system analyses sales trends over a defined period and recommends reorder quantities to maintain optimal inventory, preventing stock-outs while avoiding excess stock.

Manual Entry

This method allows you to simply enter the stock items and qty to order with no assistance.

All auto Stock

This method allows you to process orders for all stock flagged as 'Auto' and the stock screen.

All ordering methods, except the manual option, account for items already on order. For example, if you need six items but have an outstanding order for four, the system will only order two. Additionally, pack quantities and economic order quantities are enforced, which may occasionally lead to temporary overstocking due to supplier minimum order requirements.

Producing Orders

Once orders are saved the system will allow you to print or email the orders directly.

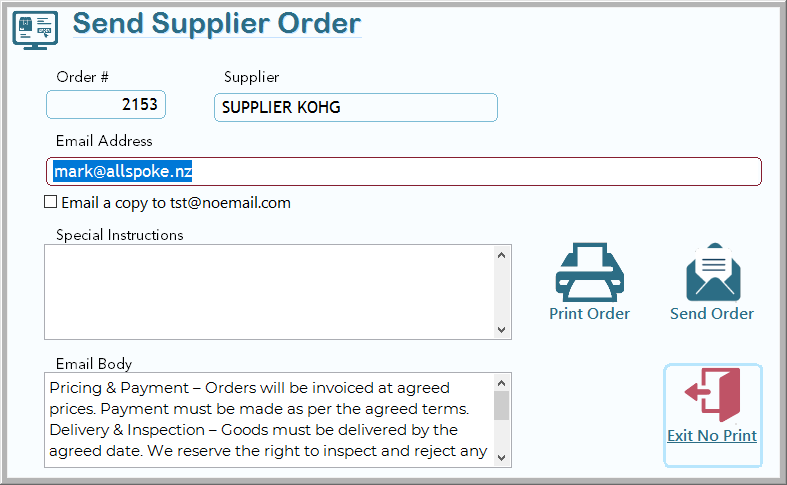

📧 Send Supplier Order

The Send Supplier Order screen allows you to quickly email a purchase order directly to a supplier. This streamlines the ordering process and ensures that suppliers receive all relevant information clearly and efficiently.

|

Field |

Description |

|

Order # |

Displays the system-generated order number. |

|

Supplier |

Shows the name of the selected supplier. |

|

Email Address |

The supplier’s email address. This is required to send the order. |

|

Email a Copy To |

Optional: Tick this box to send a copy of the email to yourself. |

|

Special Instructions |

Optional: Enter any special notes or instructions for the supplier (e.g. delivery requests, packaging notes). These will be stored on the actual Purchase Order. |

|

Email Body |

Pre-filled standard terms and conditions related to pricing, payment, delivery, and inspection. You may edit this text if needed. |

Sending the Order

- Confirm or enter the supplier's email address.

- (Optional) Tick "Email a copy to" and enter a secondary address if a copy is required.

- Add any Special Instructions if needed, these will be printed and stored on the actual Order.

- Review the Email Body for accuracy or modify if required. This will be in the body of the email only

- Click Send Order to email the order to the supplier.

- If you would like a printed copy for records, click Print Order.

- To cancel and exit without printing or sending, click Exit No Print.

Once the orders are all sent/Emailed the system will provide you with a report detailing all orders processed in the batch.

Important Notes

- The email address is mandatory. You will not be able to send the order if this field is blank.

- Ensure all instructions and terms in the email body are appropriate for the supplier.

- Once the order is sent, a record of the transaction is saved for future reference.

Why Orders in Ramsys POS Cannot Be Edited

To ensure clarity and avoid potential disputes, Ramsys POS does not allow orders to be edited once they’ve been created. This is because orders are considered external documents — they’re sent outside your business to suppliers, often triggering actions such as packing, invoicing, or fulfilment.

Allowing edits after sending could lead to mismatches between your system and the supplier’s copy, causing confusion, delays, or incorrect deliveries.

If a change is needed, you can cancel the order and create a new one with the correct details. This ensures a clean audit trail and that both you and the supplier are working from the same information at all times.

This approach prioritises reliability, professionalism, and trust in your supplier relationships.